Researchers at the University of Cambridge in England have come up with a novel way to produce a widely-used gas that is currently produced from fossil fuels.

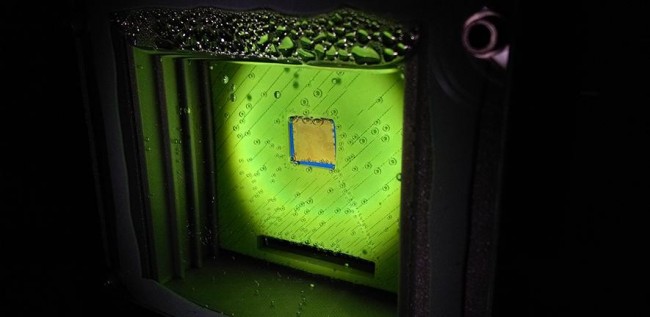

The researchers have discovered that they can directly produce the gas – called syngas – from an artificial leaf that uses only sunlight, carbon dioxide and water.

This development was first reported Wednesday October 22 in the journal Nature Materials.

The hope is that the technique can eventually be used to develop a sustainable liquid fuel alternative to gasoline (or petrol as it is known in the U.K.).

“You may not have heard of syngas itself but every day, you consume products that were created using it,” said Professor Erwin Reisner of the Cambridge Department of Chemistry. He was speaking in an interview with SciTechDaily. “Being able to produce it sustainably would be a critical step in closing the global carbon cycle and establishing a sustainable chemical and fuel industry,” he said. Reisner has spent several years working to achieve this goal.

Syngas is currently made from a mixture of hydrogen and carbon monoxide, and is used to produce a range of commodities, including pharmaceuticals, plastics and fertilizers.

The artificial leaf that Reisner and his colleagues have come up with is inspired by photosynthesis – the natural process by which plants use the energy from sunlight to turn carbon dioxide into food.

On the artificial leaf, two light absorbers, similar to the molecules in plant that harvest sunlight, are combined with a catalyst made from the naturally abundant element called cobalt.

When the device is immersed in water, one light absorber uses the catalyst to produce oxygen. The other carries out the chemical reaction that reduces carbon dioxide and water in carbon monoxide and hydrogen, forming the syngas mixture.

The good news is that the light absorbers work even under the low levels of sunlight on days when it is raining or overcast.

The research was carried out in the Christian Doppler Laboratory for Sustainable SynGas Chemistry in the University’s Department of Chemistry. It was co-funded by the Austrian government and the Austrian petrochemical company OMV, which is looking for ways to make its business more sustainable.

Other artificial leaf devices have also been developed, but these usually only produce hydrogen. The Cambridge researchers say the reason they have been able to make theirs produce syngas sustainably is thanks to the combination of materials and catalysts that were used.

Syngas is already used as a building block in the production of liquid fuels. “What we’d like to do next, instead of first making syngas and then converting it into liquid fuel, is to make the liquid fuel in one step from carbon dioxide and water,” Reisner said.

He said the development of synthetic petrol is vital as electricity can currently only satisfy about 25% of the world’s energy demand.

Capturing planet-warming carbon dioxide and turning it into useful products, from plastics to jet fuel, could make climate action cheaper and become a good business - but market obstacles need to be overcome first, researchers said on Thursday.

Companies are already turning carbon dioxide captured at industrial plants into materials such as road aggregate and low-carbon cement, scientists said in a paper published in the journal Nature.

Eventually products could also be made from carbon dioxide captured directly from the air, as the costs of that technology fall, they added.

“There are a lot of weird and wacky ideas out there, and we’re just scratching the surface,” said Cameron Hepburn, a University of Oxford professor in environmental economics and a lead author of the study.

But efforts to turn captured carbon into products are still largely small-scale because most countries have yet to put an economic value on eliminating climate-changing gases while some of the processes require a lot of energy, he told the Thomson Reuters Foundation.

Construction standards and other regulations also make creating markets for new products difficult, said Hepburn, also director of the Smith School of Enterprise and the Environment.

With emissions from burning fossil fuels and clearing forests continuing to rise, scientists now believe holding warming to 1.5 degrees Celsius above pre-industrial times will require sucking some carbon back out of the atmosphere.

In a landmark 2018 report, they said keeping global temperature rise to that more ambitious of two limits adopted in the 2015 Paris Agreement would substantially cut risks linked to planetary warming, from water shortages to wilder weather.

Scientists say carbon dioxide captured from smoke-stacks or the air could be stored permanently underground, but investment and policy to make that happen on a large scale have been slow to emerge.

In Europe, “we’re so far off trend it makes you wonder what we’re doing”, Andrew Cavanagh, an emissions storage expert at Scotland’s University of Edinburgh, told a September conference.

Instead, turning some of the carbon into products with a market value could be another way to drive investment into carbon capture, economists say.

FERTILIZER TO SKYSCRAPERS

The Nature study, which examined thousands of papers on technologies to remove and use carbon, including natural processes, to gauge their viability, predicted they could together remove between 1 and 10 gigatonnes of emissions a year.

Burning fossil fuels is currently emitting 37 gigatonnes of carbon dioxide a year, and scientists predict the world will need to remove somewhere between 100 and 1,000 gigatonnes of carbon in total this century, the study said.

The technologies assessed ranged from turning carbon dioxide into a feedstock for plastic or fertilizer production, to finding ways to build skyscrapers in fast-growing cities out of carbon-sequestering wood or even carbon-negative cement blocks.

Researchers estimate that about $90 trillion will need to be spent globally by 2030 to build and update infrastructure, particularly as the world becomes more urban and cities grow.

That could create major new markets for carbon-storing building materials, said Ella Adlen, a researcher at the Oxford Martin School and another lead author of the paper.

But attracting investment in many of the technologies remains challenging because of problems ranging from regulatory barriers to poor financial returns due to a low - or absent - price on carbon, Hepburn said.

Capturing carbon directly from the air can also take large amounts of energy, although fast-falling costs for renewables may eventually eliminate that problem, he said.

Finding just a few initial lucrative uses for captured carbon dioxide could help “prime the pump” for more, as business interests push governments to change policy, Hepburn said.

“We have this big oil and gas industry taking carbon out of the ground and putting it into the air,” he said. “We need an industry almost as big in reverse, taking carbon out of the air.”

Capturing and using carbon dioxide cannot be a substitute for switching away from fossil fuels to cleaner sources of energy, he emphasized, even though the oil and gas industry is “very interested” in the new technologies.

“We need to do both as fast as possible,” he added.

The paper’s authors differed on the prospects for the carbon removal technologies, Hepburn noted, with some highly doubtful most will succeed and others more optimistic.

John Beddington, a former chief scientific advisor to the British government who pushed for the study, warned “the risk of getting (carbon capture and use) wrong is quite high”.

“But if you do it right... you are tackling one of the key barriers to change, which is the cost of (climate) action,” he said.

Join a community

Write a blog

Pick a product

post everyday for 30 days